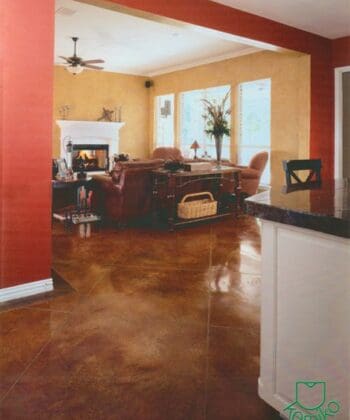

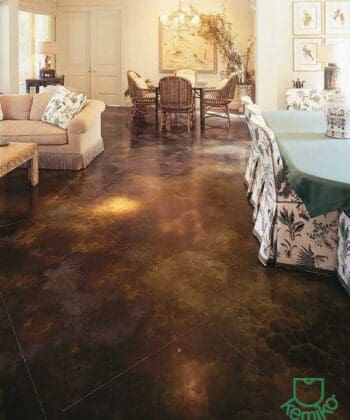

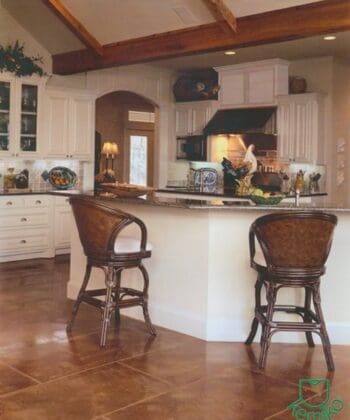

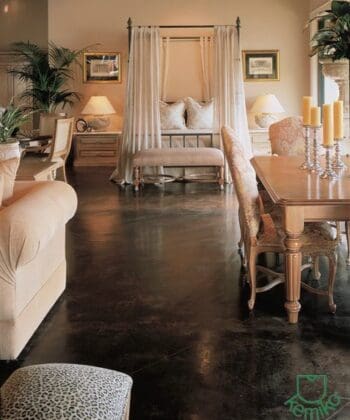

Kemiko Stone Tone Concrete Stain

Starting at: $66.06

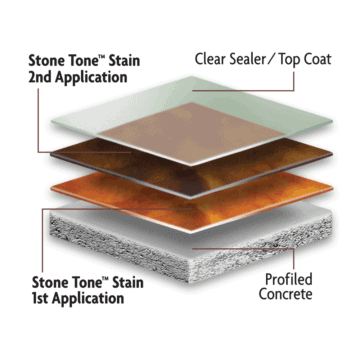

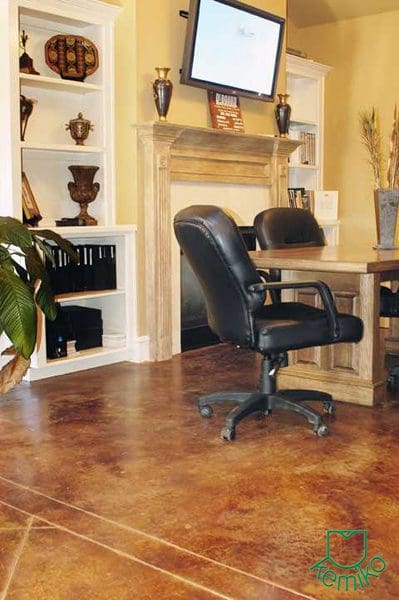

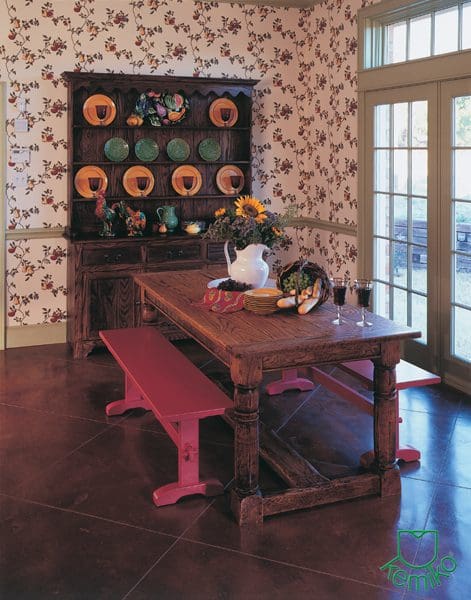

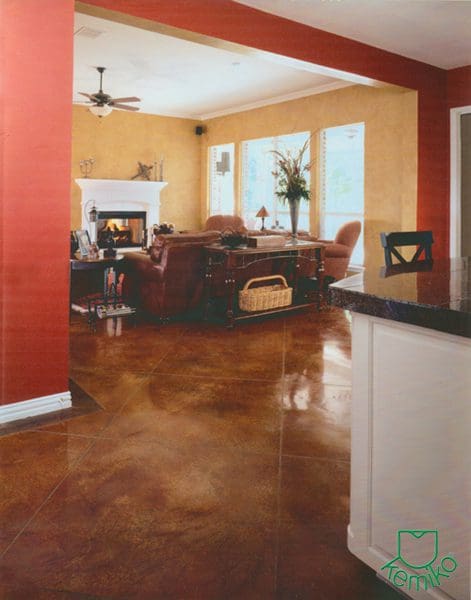

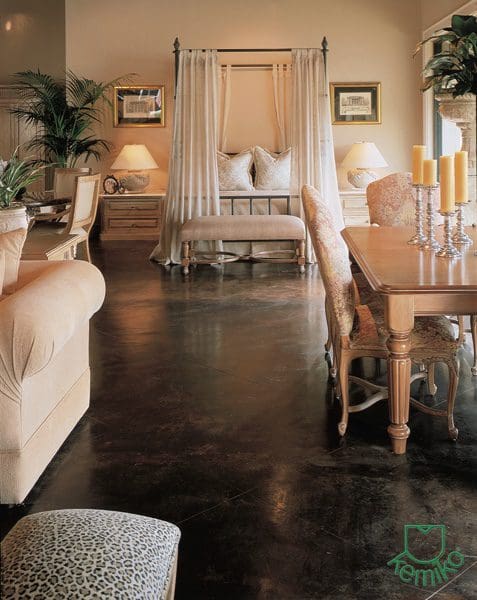

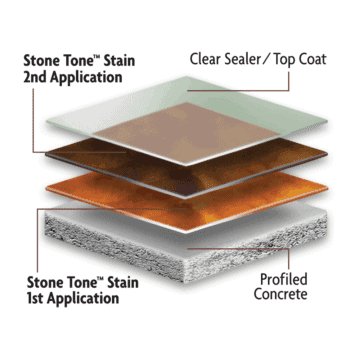

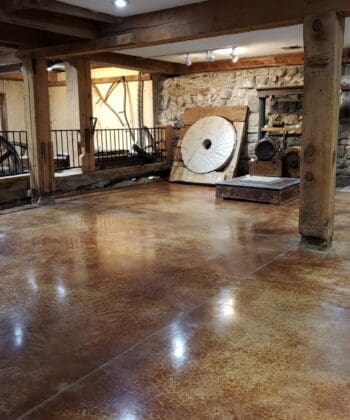

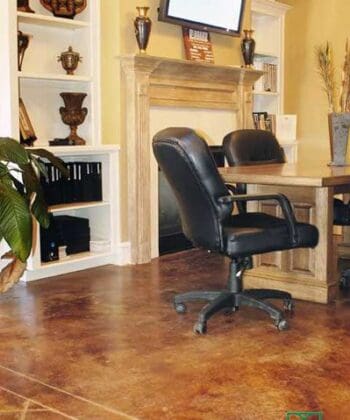

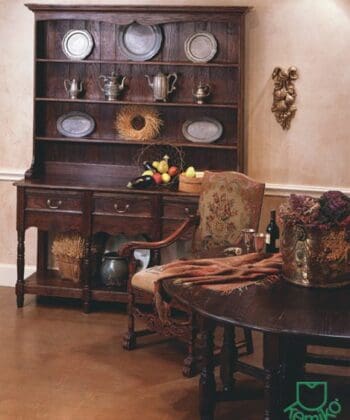

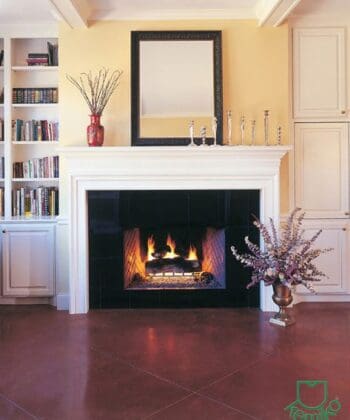

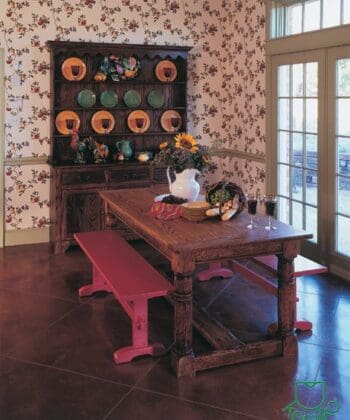

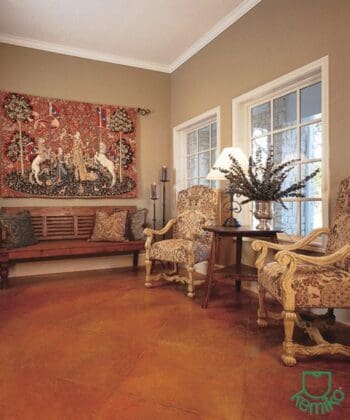

Kemiko Stone Tone Concrete Stain is a single component reactive stain that transforms an bland concrete slab into a unique floor that is just as attractive as a marble or glazed stone- at a fraction of the cost. Available in 10 colors, it will not chip, fade or peel.

Kemiko Concrete Stain may be applied to properly prepared and thoroughly cleaned concrete.

Features

- Cost-effective & versatile

- Elegant & permanent

- LEED compliant

- Low odor, low VOC

- Human health hazard free once cured (no off-gassing)

- Maintenance free

Coverage

400-800sq feet per gallon (coverage varies due to differing concrete conditions)

400-800sq feet per gallon (coverage varies due to differing concrete conditions)

Equipment

Equipment: Plastic garden sprayers, medium soft or stiff bristle brushes 10”-12” width, plastic tubs or plastic paint pans. Roller dolly fitted with rubber casters to move stain container. Sealer can be found here.

Equipment: Plastic garden sprayers, medium soft or stiff bristle brushes 10”-12” width, plastic tubs or plastic paint pans. Roller dolly fitted with rubber casters to move stain container. Sealer can be found here.

NOTE:

Any coatings, sealer, adhesives, tape residue etc… MUST be fully removed for the stain to penetrate and react.