Podcast

NTE Podcast: Flooring 201…DIY or Hire a Pro

NTE Podcast: Flooring 201…DIY or Hire a Pro

If you’re remodeling your home, there are many different flooring materials you can use and hundreds of manufacturers to choose from. It becomes overwhelming. Let’s take wood flooring. Do you want it solid, pre-finished, floating, engineered…folks, the options are many and most home owners aren’t aware why you would use one over another. Jay puts on his customer cap today to grill Andy about all these options, then they discuss the possibility of just hiring a pro to do the work.

iTunes

Google Play

Spotify

Transcript

Flooring 201…DIY or Hire a Pro

Andrew Pace: Welcome to the Non Toxic Environments. My name is Andrew Pace. Every week my cohost Jay Watts, and I will discuss healthier home improvement, ideas and options. Thank you for finding us and please enjoy the show.

Hello folks. Welcome back to Non Toxic Environments. I am joined this week once again, by my cohost Jay Watts. Jay it is the dog days of summer, isn’t it?

Jay Watts: Well, yeah, August. We’re almost into August here one more day and it’s getting warm. It’s warm here in California and I bet it’s warm and humid in Wisconsin, although I might be wrong about that because I remember last time we talked about the weather and you said, what was that? What was that slogan or saying that you have back about the weather there in Wisconsin? If you don’t like what the weather is, just wait five minutes, that’s it? Yeah. Okay. Well then give me the five minute report.

Andy: I’ll give you the ten second report. It’s been 90 to a hundred degrees with high humidity up until about a day ago. And right now it’s gorgeous. 78 sunny, partly cloudy, low humidity. This is my perfect weather.

Jay: Well, you know, this might, this lead us into our podcast themed today. We are going to talk about flooring and I think are those who have listened to us for a while and maybe say, well, wait a minute, you guys did some flooring show a while back. And we did. You’re absolutely right. Thanks for listening by the way. We thought we just revisit it. Our Andy Pace here is the resident flooring expert. And so he’ll, he’ll be kind of driving the boat on this one, but I’m hoping that as we go through the conversation here that some ideas will come to me and I maybe will act like the fly on the wall and maybe show Andy a question or two that will really, you know, pick his brain, test his knowledge base, and also share that revelation with all of you who are listening. So take it away.

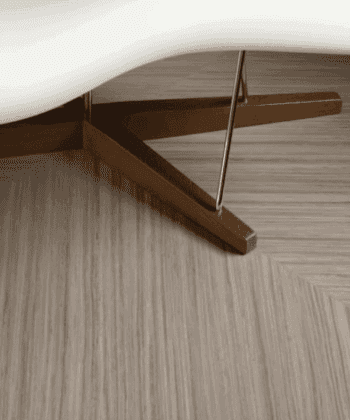

Andy: That’s right Jay we did do a show back in August of 2019, it was called New Flooring Options & Trends. We also did a show boy, when we just started this cast t was back in 2018, early 2018. You and I did a show it was called The Carpet that Covers Our Floors. And so it’s, it seems to be tradition that we do an annual flooring episode, but this one’s taking a little twist. We can talk about cork and bamboo and wood and tile and this and that, and so forth in carpet as well. Emily here in the office came up with an idea. She said, we field questions all day long from customers who want to know why you do a floating floor versus a glue down. Why is the cost from the contractor higher than I’d imagined for just clicking together some pieces of flooring? So, uh, and then what else should I expect? You know, what what’s all involved in the process of putting down linoleum? So, you know, we thought this episode would be good to talk about more of the details, not necessarily brands and so forth, as you can get opinions everywhere about that. But how do you actually do it and what to expect? So you’re not shocked or surprised.

Jay: Okay. So I’m going to be one of the callers and I’m going to say, Oh my God, you know, I really want to do on a linoleum floor, but I’m a little unsure and uncertain about the installation. I’m worried about the glue, are we gluing it down to concrete sub floor? I’m kind of lost, help me out on this.

Andy: Excellent. My first question back would be, is this a slab on grade concrete or is this an elevated concrete deck?

Jay: It’s on-grade so a slab. I mean, I think it’s on grade. I mean, am I right about that? It’s like on dirt, right? It’s the dirt, right?

Andy: This could be mean that it’s just a slab on the top of the dirt, or it could mean even a slab in a basement floor, but essentially we’re dealing with the same type of situation. So with concrete slab, there’s always a potential of moisture vapor coming up through that slab. So we would asked the client, have you done a moisture vapor test? Either what’s called the calcium chloride test, which is very detailed, gets you right down to how many pounds per thousand square feet of pressure is there coming to the floor or have you done the cheap and easy test, which I recommend was take a black plastic bag, tape it to the concrete all the way around, let it sit for two to three days and then peel it up and just observe is it darker underneath that plastic? Do you have moisture building up on the underside of the plastic? That tells me you’ve got vapor transmission.

Jay: Yeah, I think I’ve heard about that technique. I saw it on the internet or something like that. The other test you mentioned is that a test that have to have a pro do? Or is there something I could, I could do myself or?

Andy: You know, I’ll put a link in the show notes to this. Homeowners can do it themselves. Good quality flooring installers should do them in situations where it’s uncertain, what type of vapor pressure there is. The reason why you do this tests. And so let’s say you did the black plastic bag test, and you did find some moisture. Now, the next test to do is the calcium chloride test, because you’re talking about 50 bucks a test. If you bought them off of Amazon, and then time to do it. When you’re putting down a flooring material in this case, we’re putting down linoleum. If the pressure coming through that slab is greater than, let’s say five to six pounds of pressure. And you don’t necessarily need to know why I’m using that as the metric, but just understand that’s what’s allowed by the manufacturers technical information for how well their glue will stick. It it’ll stick all the way up until the fact you got more than six, five or six pounds of pressure, it’ll start to peel. So if you have more than five or six pounds of pressure coming through a floor, now you have to decide, do I put down, what’s called a moisture limiter coating? This is a type of coating specifically designed to keep that pressure from coming through. There’s no such thing as a healthy version of this, by the way. Or do I float the floor? So the question then comes to what what are you trying to achieve with a linoleum floor? Your own imagination is what you can do with a glue down linoleum floor. You can cut it to any pattern you wish and have a glue down professionally, okay. With a floating floor, you’re limited to the geometric shapes that those floating tiles come in. However, because it’s a floating floor, you have to by the manufacturer’s instructions, you have to put down a vapor barrier, which is at least a minimum of six mils of plastic. Mill is a 1000th of an inch. So it’s six thousands of an inch of plastic. And that keeps any vapor pressure from coming through. So now that vapor pressure issue we were talking about before, isn’t much of an issue anymore.

Jay: You know, you’re making me think of something that might be a little worried about. The one thing, just the last thing you mentioned… if I have a piece of plastic and I’ve got moisture or vapor coming up under the plastic, what should I be worried about mold getting underneath there? I’m a little worried about that.

Andy: The way that a floating floor operates is that because that actually doesn’t get fastened or glued directly down to the ground, there is a very slight air gap. Now you can do things to the sub floor that actually give you even more of an air gap. There are actually materials you can use underneath a floating floor that will give you about a 16th to an eighth of an inch. And that allows any moisture vapor that comes up. And I’m not talking about water folks. I’m not talking about, if you have a leak, a hydrostatic pressure leak, a crack in the floor, and it’s pushing up water, I’m talking about vapor. And so that vapor comes up and hits the underside of that plastic. And then it usually then will travel along the underside of that plastic and then go up vertically behind the base molding of the flooring material.

Jay: Alright, I think I understand it.

Andy: The more pressure you have, the more concerned you should be about what you say, what if it’s actually water, then you have to look at other things.

Jay: Yeah. The other, the other thought is, are we gluing anything? And if we’re gluing, I’m a little nervous about the glue that might be recommended by the manufacturer of the flooring. What do I do if I want to substitute into adhesive? Can I even do that?

Andy: So far we’ve talked about the floating method and the situation, but if you decided that either the vapor pressure was good, or you wanted to do some more custom patterns and you wanted to do a glue down version, the glue that’s supplied, you know, and I know Forbo really well, the Marmoleum product, and I know that their adhesive is very, very safe. I’ve never had a problem with it, with any of our clients. Can you use the AFM 3 in 1 Adhesive with this, you can, but you run the risk of avoiding the Forbo warranty. And so that’s kind of a decision you have to make. I’m kind of a big believer that if you’re spending a lot of money on a floor, you want a warranty.

Jay: Yeah. I do want the warranty. I guess kind of on a simpler level, the question is, should I really even be worried about the adhesive off gassing, I mean, wouldn’t the vinyl or the linoleum be like a barrier?

Andy: It would, and that’s a really a great point. And you can actually use this point on a variety of materials that we’ll talk about today. Once you cover up that adhesive or that material that’s underneath the floor, there’s almost an impossibility of a high amount of off gassing or even a very slight amount. It’s possible you could get some traveling from the perimeter of the room, but off gassing folks is not like pressure that builds up and it pushes out wherever I can. It’s more like dust coming off of a surface. And if it can’t come off that surface, it’s not going to find its way out.

Jay: Oh yeah, yeah. I guess just one last question on this. If someone wants to come and put another floor over the linoleum, they decide they want wood floor, is there anything special that I would need to be aware of? I don’t need to take the linoleum off, right? I can just leave it there and go right over it?

Andy: This is a good question for folks who are looking to put a floor down and may eventually want to sell the home, keep in mind, linoleum specifically, the glue down version of linoleum is designed to last 50 years in a commercial application. In a residential application the house will probably fall down around it. Alright, so the question comes up, well, what if I want to sell my home? And the people who are looking at my home don’t have the same taste that I do. Maybe they have no idea what real linoleum is, and it might turn them off. So, yes, you can float a wood floor over a glue down linoleum, very similar to floating a wood floor over a glue down vinyl. If it’s a floating linoleum already and floating, cause we really haven’t talked about, is essentially these pieces that click and lock together and you just lock them all over the floor, but they’re not actually physically attached to anything except for the next piece. The entire floor floats as is as if it’s on an island.

Jay: I’ve seen that. I’ve seen that

Andy: Because of that though you can’t put another floating floor over it. So if you do have a floating linoleum floor and you want to put something new down, you have to remove that to put your new floor down.

Jay: I had one more thought and that is, I’m also considering we’re pretty sold on the linoleum on our concrete down on slab, but we’re also thinking about upstairs. One of the rooms upstairs, we’re thinking about doing a pattern, like you said earlier, you know, doing a pattern linoleum because it’s where our kids hang out and we’re thinking I’m wanting to do a linoleum floor there, but I’m wondering because it’s upstairs. Is there any worry about sound attenuation, meaning is it going to squeak or is it gonna, are you going to hear us bouncing around up there or is there something to that is in the industry for this that would help with sound reduction or is that a possibility or is that not necessary?

Andy: Definitely a possibility. Keep in mind, natural linoleum that gets glued down is a little less than an eighth of an inch thick. Okay. Sound and vibration does travel through it. Now it does have the benefit, one of the components of it is actually cork. So it does help to sound deaden vibration slightly. But if this floor is going to be used for a playroom, if it’s going to be used for a yoga room, a gym and believe me, we’ve installed natural linoleum and a lot of commercial gym floors. Forbo offers an underlayment called their Corkment, which is essentially an eighth of an inch thick of cork that gets glued down to the sub floor first. Okay. And then you glue linoleum to it. Oh, it obviously adds to the cost, but long term solution, it’s a fantastic way to go and keep in mind, natural linoleum contains linseed oil. Linseed oil is naturally antibacterial and anti-static so keeping that floor clean for your kids, you’re using in a gym where you’ve got sweat dripping and so forth. It makes the room cleaner. And in today’s days of pandemics and COVID, thinking about using materials that have built in antibacterial agents that are completely natural and not harmful. Yeah. That’s a good thing.

Jay: Sounds like a perfect thing. We also own a little vacation property out near the coast here in San Diego. And we’re thinking about right now, I think it’s actually an old floating floor, to be honest with you. There’s some, it looks like something you might have bought at Home Depot. Whoever was in there before us, but we just got it. So it’s new for us, but we’re wanting to upgrade it a little bit and this old floating, I think floating floor in there and it’s not looking very good. So, we’re thinking about putting, we want to put in reclaimed hardwood in there. And I don’t know what Pandora’s box I’m going to discover when I start pulling it up, I guess, because several many questions flood into my mind about this, but so I’m going to remove it. And I guess, I guess the first question is what do I do with it when I remove it? I mean, is it land fillable or how would I handle it?

Andy: Depends on what the material is, what shape it’s in. It’s quite possible that if the floor’s in decent enough shape, it can be donated to Habitat. Otherwise, the sustainable thing to do would be to try to refinish it. Otherwise, if you have to, because there’s too much damage and so forth I would talk to your local municipality to see the best way to dispose of it in a friendly manner. But at that point, the world’s your oyster far as what you put down.

Jay: Yeah. It doesn’t look that bad, but we don’t like this aesthetic of it. And I guess the other question that comes up is since it’s near the coast, I mean, even we’ve got a lot of moisture, a lot of humidity and I’ve never done a floor installation, a hardwood floor installation. So I’m just interested in what you’d say in terms of what I need to think about and putting it down correctly, especially in a place where I don’t have any moisture coming up as we, the other thing we were talking about with the linoleum, I don’t have that problem or worried about atmospheric moisture and what I need to be concerned about there.

Andy: So installing wood in a higher humidity situation can be tricky. I’ve been involved in too many projects where people installed a floating wood floor, even which gives you more room for flexibility. Two weeks later they’re calling up complaining that their floor cupped, meaning it rose up pieces are actually swelling so much. There’s no more room to move and they start to raise up and curl. So most importantly, when installing wood in a higher humidity situation is understanding the species that you’re working with to make sure that it is good for a higher humidity installation. I won’t get into detail as far as which ones right now, but I will say this, talk to your supplier, find out which ones are good for your area. The other thing is make sure that you acclimate the wood to your environment prior to installation.

Jay: So that means you bring it in and you let it sit in the space. So it can kind of get used to this space.

Andy: Exactly. Right. We see this both with wood and with bamboo, another product that’s still pretty popular. Bamboo can take sometimes three weeks to acclimate to the temperature and humidity of the area that it’s going into. And if you don’t allow it to acclimate, you’re going to shock it and you’re going to install it. And all of a sudden it’s gonna shrink or swell or pop it’s going to be a mess.

Jay: Do I have to lay all the boards out individually so that they can acclimate or do they stay in a stack? How do they acclimate actually?

Andy: Let it stay in the box in the box. Now every manufacturer has a different way to do it depends on whether it’s a floating floor and nailed down, glue down, whether it’s engineered or solid, but essentially the most situations are, keep it in the box. But if there’s any plastic wrapping, remove the plastic wrapping from the box. Sometimes they’ll ask you to open up the ends of the box, but keep the material in the box so it’s nice and tight. And then sack the boxes, kind of like you’re building Lincoln logs, allowing for air movement all around the boxes.

Jay: Should I let the sun hit it?

Andy: No. No. Put it in the room, don’t let it heat up because of the sun, because what’ll happen is only certain boards will heat up and you’ll have uneven movement. So just keep it in the room in the box. Again, defer to the manufacturer’s instructions on how to acclimate, but once it’s acclimated, then you can install.

Jay: Oh, okay. That sounds pretty easy. I was a little worried about that for a second. Yeah, I did I tell you it’s reclaimed, does that make any difference?

Andy: The reclaimed can make a difference just because with the reclaimed wood, quite often you don’t really know what it’s going to do because there’s no historical reference to how it moves.

Jay: I guess that could be a problem with finishing too.

Andy: It really could be. I quite honestly, I’m not a big fan of using reclaimed wood for that reason because you just don’t know what you’re going to get until it’s too late.

Jay: Yeah. And it’s more expensive too.

Andy: Now question that comes up a lot from customers is okay, maybe I’m not going to do this myself. I mean, there are DIY products. And then there are products that can be DIY, but if you want it done quickly and you want it done accurately, you should probably hire a pro. And I’ll say that 98% of the floors that we sell are in this situation. If you’ve got the tools, if you’ve got the time, if you have some experience, you can install a floating floor, but if you want it done quickly and accurately, and you just don’t want to have to deal with the mess, with the details, then you need to hire a pro. So let’s look at a floor material like a luxury vinyl tile, because we do this or luxury vinyl plank. We do this material quite often, the Cali Vinyl products. I’ve never been a big fan of vinyl. This particular product really blew me away as far as its durability and his lack of off gassing. So we sell a lot of this product. It’s not that expensive looking at other flooring materials. You’re talking about less than $4 a square foot for material, which is really a good value for a product that has such a long life span. However, if you hire a professional to put down something like a luxury vinyl plank floor or any other floating floor people ask, well, why is the labor so expensive to put that down? I thought you’re just cutting pieces and clicking them together and put it top of the sub floor. How can labor sometimes even be more expensive per square foot than the material itself? And again, we get this call quite a bit because in today’s day and age of Home Depot and HGTV and people thinking they can remodel in a weekend, they want to try putting the flooring down. And then when they decided they just can’t really do it and they want to hire somebody, they can’t fathom why it’s so expensive to put down. And here’s why, because when you put down a floating floor or any floor for that matter, just think about some of the things that you and I have talked about already Jay, we’ve already talked about having to assess the sub floor, maybe even remove the flooring that’s there. What if that flooring is nailed down wood that has to be removed or glued down vinyl that has to be pealed off. What if the concrete slab that you talked about Jay, requires a lot of patching because there were some old pits and cracks and crevices that needed to be addressed before the floor goes down. So there’s a lot of preparation work involved in making sure the sub floor or the surface is ready to go.

Jay: Sure. It makes sense.

Andy: Then there’s the cost of actually measuring, cutting and installing the flooring material. And really when it comes to a floor layer, this is not necessarily the most difficult part of the job. This is more the fun part of the job, but it’s not the most difficult. The most difficult then comes in doing all the trim work. Remember that if you’re installing a floor material that goes from a kitchen down a hallway to a couple of bedrooms everywhere there’s a door opening. Every one of those door jams need to be cut down or what’s called undercut to allow for the flooring to go underneath it. So you have a nice, smooth transition without a lot of gaps, right? Every space you have a gap, whether it’s around the perimeter of the room, around some, a column, all those need to be addressed with trim pieces. And those trim pieces are what’s called architectural millwork, and can get expensive. There’s a lot of handwork involved, there’s materials involved, and then there’s travel time involved for the contractor maybe to come back for a second day or maybe even a third day. So when you start to look at all the costs involved, you think, yeah, it’s going to cost me. Let’s say it costs the same for the labor than it does for the material. And you think I could do it myself and save all that money, but will it be done in three days? Will all that flooring material that you had to rip out, how are you going to dispose of it and you have to pay to dispose of it?

Jay: Yeah, it probably in my case it would probably take me a day just to figure out that I did it wrong and then have to start over. I see the wisdom in hiring pros. I’m wondering what’s the best way to find a pro is like word of mouth or Angie’s List or…

Andy: Word of mouth for me, word of mouth from a family member or a good friend, or even a neighbor who you know really well, if you notice that somebody was just there doing some work, you can say, Hey, what type of work did they do? Did you like them? Where they were they on time? Were they courteous? Were they honest and upfront with their pricing? Most importantly, did they give you a written quote? Are they bonded and insured?

Jay: I was going to ask about that, what kind of quote/unquote contract should I be looking for?

Andy: Perfect. Think about finding contractors. Number one, good contractors are hard to come by, especially these days because there’s right now from coast to coast, it’s never been as busy and remodeling as it is right now. And you know, even locally here, our installers are running three, four weeks before they can work your project in. We have crews. So that’s how busy it is, right? If same here, if you’re not in Wisconsin and you’re listening somewhere else and you don’t have family or friends or neighbors to give you any good names, then I’ll ask you to go to a website called NARI.org. NARI stands for the National Association of the Remodeling Industry. Folks, contractors, subcontractors, installers, who are members of NARI and then get certification through NARI. They have to go through some pretty strenuous educational events and testing in order to get those certifications. And so for me, and on my projects, if I don’t know somebody to reach out to myself, that’s the first place I’m looking, find a local NARI chapter, see who the members are and then start going down the list.

Jay: That is really great advice. So how did I do as a client? I almost feel like we only dipped into the pool just with our toes.

Andy: You dipped in a little bit. I want to wrap up, tidy up some of these things, because there are a few things that I just want to make sure we get out there because of again, what is happening across the country, with all these projects and questions are the same question are, or three come in all the time. One is, I’ve got a lot of pets. What’s the best floor material for pets. You know, porcelain tile, because it’s the least likely to scratch or finished concrete, will be the best. But the question or the response I usually give is, well, as long as if you’ve got a big dog or a lot of them, as long as their nails are clipped and as long as you clean up their spills quickly, you can use a variety of flooring materials, but understand that with pets, there’s a level of flooring material that you’d probably want to stay away from. Those would be your softer woods. I’d probably stay away from carpet, for a number of reasons, but pets and carpet don’t really mix because not because of just because of the fact of spills and accidents, but because pets are lower to the ground. And they’re closer to that chemical off gassing from carpet I’ve seen all too often family pets friends coming down with rare diseases and tumors because of you find out that they have a whole house full of carpet.

Jay: Oh boy. All right.

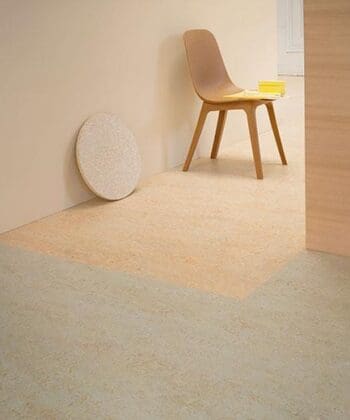

Andy: Now speaking of carpet, the next question I get is after I’ve convinced a family to put a floating cork floor throughout their entire house, what if I want something really soft under my feet in the bedroom?

Jay: Right? Which of course the most do.

Andy: Most do. At that point we say area rugs, area rug made from a known company, something like an Earth Weave product where it’s chemical free, limit the amount of carpet and especially, or use a healthier carpet like Earth Weave or Nature’s Carpet. You will limit the chemical exposure. I’m a big fan of doing hardwood throughout the house, or the Amorim Wood Wise throughout the house. And then just putting an area rug where you absolutely need something soft under foot.

Jay: Yeah. That’s what we do here in our home. We have old Doug fir floors and we have area rugs that work out nicely. And the nice thing about an area rug is that at some point, if you grow tired of the pattern and color, you can just replace it. And it’s not a big disruption.

Andy: Exactly, exactly. And keep in mind that a well installed floor that’s designed to last as long as the home will always maintain value. I’m not going to say maintain a hundred percent of the value. Very few things in a home remodel will, but a carpet is designed to be replaced. A good quality wood floor, natural linoleum floor, cork floor, these products designed to last a very long time. So that value will go with you, go with the sale of the home.

Jay: Yeah. I’m trying to think of a situation where a beautifully kept hardwood floor would not be a selling point.

Andy: Exactly. Now the last thing I’ll talk about is bathroom floors. Bathroom floors, you know, traditionally we would use a porcelain or ceramic tile or a natural stone. And of course they’re good for a variety of reasons, easy to clean, maintain so forth, but they are hard. They are cold. They are difficult to stand on for long periods of time. And so we’re starting to recommend a product called Amorim Wise. And I just mentioned it before- Amorim Wise is a kind of a hybrid solid cork product. Now we all know cork flooring that, that you see in magazines and so forth. And when you do most internet researches, the cork flooring you find is actually what’s called a traditional engineered cork flooring and engineered cork flooring is essentially a thin layer of a cork veneer on top, with a little bit of granulated cork underneath that. And then I thicker layer of medium density, fiberboard- wood. And that’s the core of the engineered cork Amorim cork is different. The Amorim Wise is actually solid granulated cork with either a thin veneer of real cork or a recycled PET plastic surface that’s printed to look like wood. What I love about this product, no off gassing. Alright, zero off gassing, we’ve done FRAT testing and no formaldehyde whatsoever. It’s designed to be used in residential and commercial installations, folks. It’s actually warrantied in commercial installations. It’s warrantied in high moisture situations, kitchens and bathrooms, no big deal. Now, how do you float, it’s a floating cork by the way, how do you float a floor if you’re doing it in a bathroom, I’ve talked about this for the entirety of my career. You can’t float a floor in a bathroom because the toilet becomes a pinch point. Your floor tries to move in a buckles because the toilet clamping down, here’s how we get around it. We glue it down. We glue down the Amorim to the sub floor. It still clicks and locks together, but it’s in a bed of adhesive and now the floor is set. It’s not going anywhere. And you have all the advantages of a cork floor. It’s warm, it’s quiet, easy to stand on. And it’s also, does contain an ingredient called subaron, which is the natural sap found in the cork oak tree and that too, is antibacterial.

Jay: Do I have any problems if I’ve got a radiant heated floor, is that going to have an impact in some way that I need to be aware of?

Andy: It is. And that’s a great question, because we’re certainly advocating for radiant floors more often. If you do have a radiant floor, we have to determine whether it’s hydronic. So the tubes that are in the sub floor or electric. Once we’ve determined that then we can start talking about the flooring material. Cork, because it’s a very good insulator. That also means that energy doesn’t go through it very easily. Cork is a great flooring material if you have forced air heating, or if you have radiant electric panels or a radiant, hydronic piping around the perimeter of the room, because it warms up surfaces right in a warm up that cork service and stay warm long. But if it’s in the floor, underneath the floor cork, wouldn’t be your best choice.

Jay: Tile would be better?

Andy: Tile is good for heat. Yeah. A wood is good for heat and a little bit of comfort. Okay. If you really insist on wanting to use cork, you can, but understand you’re gonna have to turn up the temperature in order to get that same heating factor. So energy costs will go up actually in this situation, natural linoleum.

Jay: Oh, there you go. Makes perfect sense. Okay.

Andy: So what do you think, Jay, me as a flooring salesmen?

Jay: Boy, I’ll tell you what I’m sold. I’m sold, I’m ready to come down and spend some money with you, Andy.

Andy: Well, most important for me is, and I’ll be blunt and honest with everybody, and this is the way I’ve always ran my career. I, when somebody calls up and starts asking these types of questions, we probably turn away more business because we are honest. And I never want somebody to buy a floor or any product from us, and then find out the hard way, two years later that we didn’t give them all the information. And they say, why didn’t they tell us that? So if somebody says, can I use a floating engineered cork floor in my shower? I’m going to tell you, you can’t and don’t ever buy it from somebody who says you can. We would rather that you get the right information and sometimes you to take step backwards to take two steps forward. Sometimes you’ve got to use a material that ultimately you’re not in love with because it really is the best material for your job.

Jay: Yeah. I think there’s a lot of eye candy out in the world there with Pinterest and the other places that people can look at these great ideas.

Andy: That’s right. So on that note folks, that is the end of the episode this week, Jay, thanks again for being here and being that customer and grilling me on those features. I greatly appreciate it. If you have any questions or any comments about the show, please drop us a line. Andy@degreeofgreen.com, we’d invite you to go to iTunes and leave us a rating and a review and tell us how we’re doing and how, if you enjoy the show, let your friends and family know about it. Folks, we are the number one show on iTunes platform for healthy homes and healthy materials. And we greatly appreciate that. We don’t take that too lightly. It’s that we are just very grateful for your listenership. With that folks, we’ll be back next week with another excellent episode of Non Toxic Environments. Be well.

View Transcript PDF