Podcast

NTE Podcast: Wow, Season 5 of NTE!!

NTE Podcast: Wow, Season 5 of NTE!!

That right folks, season 5 is starting off this week. Time really flies when you enjoy what you do. Jay and I are discussing indoor air quality testing, cabinet finishing and a little bit of this and that. Welcome back!

iTunes

Spotify

Transcript

Wow, Season 5 of NTE!

Andy Pace:

It is cold outside Wisconsin right now, about 25 below zero. But things are heating up here in the Non Toxic Environments office. Jay and I are back with season five of the show. We couldn’t be more to share with you. So here we go. Happy 2022, folks. Welcome back to Non Toxic Environments. Jay, it’s been a while since we’ve been behind the microphones, but it’s great to be back.

Jay Watts:

It sure is. It’s a brand new year. And we got a lot of exciting things that we’re going to be talking about this year, and we hope all our listeners are eager to hear and share with us their own input. And we always ask for people to send us emails and throw questions at us that can tie us in knots. We love that.

Andy:

Right.

Jay:

So let’s get started. In fact, I think we’re going to start with questions from the mail bag, aren’t we, Andy?

Andy:

I think so. Honestly, folks, it’s been several weeks since we’ve been podcasting and being able to be with you. And typically, the holidays brings a little bit of a slow down in business and we get a chance to take care of paperwork that we haven’t been keeping up on when we’re really busy, but it’s been extremely busy. And this pandemic has caused just a disruption in how projects are getting done. And we’re not seeing that typical slowdown. We’re just seeing a constant movement of projects. And we’ve gotten a lot of questions coming across in the mail bag the last few weeks. And so I thought it would be a good idea if we just went to some of these for our first episode of the year.

Andy:

First off, this is from Judy. She says, “First, I want to say, I really appreciate your podcast, which is so informative and interesting as well as how well product info is available on your website.” Thank you, Judy. We appreciate that. “I would like to build some plywood kitchen cabinets and was wondering if AFM Acrylacq is the best bet for water resistance and longevity, or is there another sealer you’d recommend? The cabinets will be made from Birch maple or Hickory pure bond plywood. Also, if you have any ideas for butcher block countertop, sealers and cutting boards, that would be greatly appreciated. Thank you so much.” What do you think, Jay?

Jay:

Well, I think in terms of installation, these types of installations are probably the one that have the most expectation wrapped around them, in terms of performance of a coating. I know over the years, you and I have talked about this and we get to ask the question all the time. So yes, I would agree with the observation of Acrylacq.

Andy:

Okay.

Jay:

And we developed it specifically for wooden surfaces and it is the… Folks that word Acrylacq, and we get asked to spell it all the time, because it’s actually a word that we invented. It’s a hybrid between two words. The first word is acrylic, and the second word is lacquer. So if you split those words in half, you get Acrylacq. And the notion there was to try to communicate the idea that Acrylacq is a replacement for solvent lacquers. It is a water-based lacquer and lacquers of popular finishes in the woodworking world have been for long, long, long, long time.

So of course, in our desire to try to replay place toxic products with less toxic, safer ones, we invented Acrylacq. So I’ve used quite a bit of it, myself in my projects. In fact, to be honest with you, I do have it on my kitchen countertop, and it’s done remarkably well with the caveat. It is not bulletproof. And so you have to be more mindful about your care. And so basically what that means is, if you’re working hot and heavy in your kitchen, like I am. And I know, Andy, you are too, because you love to cook, you and your wife. You just have to be mindful of what’s going on. If you’re spilling a bunch of stuff on your countertop, you have to deal with that. You can’t just let it sit there. Wet dishes or wet bowls or anything you set on the counter. You don’t want to leave them overnight, you want to take that… Get that moisture off of there as quickly as you possibly can. I mean, quickly as possibly can within an hour.

Andy:

Right. But for cabinets…

Jay:

Cabinets is not the same.

Andy:

Yeah.

Jay:

Cabinets are a different story.

Andy:

I think she’s looking for two different recommendations, one for cabinets, and one for butcher block countertops.

Jay:

But that’s the one I took on first. So if you’re mindful of that, it can do the job. I’ve been happy with… Mine needs to be refinished right now because it’s been, wow, it’s been seven years, easily seven years.

Andy:

And that’s for your countertop?

Jay:

That’s my countertop, next to my sink.

Andy:

That’s amazing. That’s amazing.

Jay:

So my sink is on one side of this space and on the other side is my stove.

Andy:

Right. Well, it’s interesting, I’ve recommended Acrylacq for years.

Jay:

Yeah. You’ve used it too.

Andy:

And I know AFM also has the pigmented version, it’s called Ecolacq.

Jay:

Yeah. Eco.

Andy:

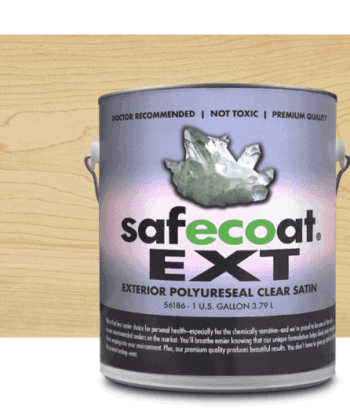

Ecolacq is essentially a cabinet and furniture grade paint for all intents and purposes. It’s thinner in viscosity. So it’s designed to be sprayed on. It gives you that professional painted solid color look and both the Acrylacq and the Ecolacq are just wonderful products. But let me tell you just a little tip that I’ve I’ve developed in the last year or so, Jay and everybody listening, is we’ve gotten this question quite a bit where people want to know what is the most water resistant coding you have? And I bring this up because Judy asked in her question, best bet for water resistance. Well, in kitchens, I think Acrylacq is perfectly acceptable without question. But you get involved in some bathrooms and bathrooms that maybe have… You’ve got kids that are splashing water all the time and maybe you don’t have great ventilation. So there’s standing steam in the bathroom. I’ve been using the AFM exterior polyurethane as a finish coat on bathroom cabinetry for the last year so, and I absolutely love it.

Jay:

I have to do that. I haven’t done that yet.

Andy:

Well, I would give that a shot. I think that it’s available in both gloss and a satin finish. And so you’ve got some option there. It works wonderfully. It’s about the same viscosity as Acrylacq. So you don’t really have to change your application techniques and yeah, it gives you that moisture resistance. Acrylacq, again, it’s a water based acrylic. Exterior poly is a water based polyacrylic but it’s been manufactured to be more moisture resistant. It’s designed to be used exterior. So that’s an option. And for butcher block countertops, I always recommend your clear penetrating oil.

Jay:

Yes. Yes. That was going to be my other suggestion. I want to back up just a little bit. So talk to me about preparation there for those cabinets. You’re going to put Poly EXT on them. What’s your general prep going in? Let me back up. Let me define what we’re walking into because that’s always the question we ask. Right?

Andy:

Right.

Jay:

People come to us and say, we’ve got to finish something. We have to know what’s there before we start talking about it. And so I’m going to say, I have an old… These are old cabinets that had an old… Some kind of old varnish or something on them. And I like the look of the wood. I just need to get a new coating on here. What do I do?

Andy:

Okay. So every manufacturer will say the same thing. And so we also tout this. It’s got to be a clean sound surface, ready to adhere to. And what that means is if you’ve got an existing finish on it, that probably needs to be sanded. If you’ve got existing stain, you have to do some testing to make sure that once you’ve sanded the finish, that the new coating, whether it’s the Poly EXT or the Acrylacq will adhere properly, because it could be an oil-based stain that was used. And maybe there’s some compatibility issues.

So you always want to test for compatibility. But once you’ve developed that sound surface, then it’s typically an application of the Acrylacq or the Poly EXT gloss. I would say usually two coats of gloss. And now your final application can be either gloss or satin in the case of the Poly EXT or gloss, satin, or matte, as in the case of the Acrylacq. You always want to build up your base coats with the gloss and do your final coat in the gloss, satin or matte. If you wanted to achieve that sheen, because then you won’t get any hazing, any milkiness of the coat.

Jay:

That’s what people we’ll ask a lot about, because we say you want to use gloss and they think… And the way it’s… I think they misunderstand, they think the only way they can get a lower sheen is to use the gloss. And that’s not exactly accurate. What Andy’s alluding to is that in the gloss, you’re maintaining the clarity, the wood figure, the grain, the color if you’ve stained it or the natural color of the wood itself. As you start to put on other coats, lower sheen coats, those lower sheen coats have a flattening agent in there that makes up the lower sheen.

Jay:

And so if you were to pile those on top of one another, what happens is that flattening starts to build up what’s a little bit of a haze. And so that’s something you really, especially on dark surfaces, it’s more noticeable. On lighter surfaces, you might not notice it, but we want to make you aware of that so that you know to keep the clarity you desire, that’s the appropriate way you lay down gloss. And then your very last coat, in a multiple coat application, would be your lower machine. Exactly.

Andy:

Exactly. Exactly. Excellent. And then again, for butcher blocks, the idea of using the Clear Penetrating Oil is because when I hear butcher block countertop, that tells me that’s something that you’re going to be preparing food on, cutting vegetables, and so forth.

Jay:

Yep. Yep.

Andy:

And so you’d never want to use anything that’s got a coat to it. For instance, your own countertop, Jay, because it’s an Acrylacq coat, if you were to cut on that surface, you could actually cut the coat and end up chipping it off and they can get into your food. So you always want to use an oil when working with a butcher block because of that food contact.

Jay:

I have two cutting boards. I have a real big one, which I do the bigger stuff on, and then I have a dedicated one for onions and shallots and that kind of thing. And they’re both oiled. So it’s like a butcher block. Yeah. Folks don’t ever cut on your countertop unless it’s a butcher block countertop and you usually shouldn’t do that anyway. Get a cutting board and cutting board. That’s what cutting boards are for. And there’s beautiful ones out there and that’s what you should do. All right. Well, I think we covered that one pretty well. Oh, sorry for the pun, folks. Here’s one. This is Jillian is in Arizona. Oh, this is interesting. How timely. “We’ve just moved into our new home and are overwhelmed by the off-gassing.” Boy, haven’t we heard that before. “Do you have a recommendation for air testing that we can do ourselves? There seem to be many options, which makes a decision on the best ones really difficult. Thank you.”

Andy:

Wow. That is good timing.

Jay:

It is.

Andy:

And so let me just back up a bit and say that I get questions quite often from customers. Where do I find the best rate on test? Where do I find the best VOC test? If I were to buy a VOC meter, which one should I buy? So on and so forth. And we all know, or you all know that I do what’s called these FRAT tests, which is the formaldehyde release tests. And over the years, I’ve worked with a company in Michigan that that does air quality testing that is essentially self administered. So they send you a little box. It’s an air pump. And you turn it on. It collects air in these tubes for a period of time, turn it off, cap it, send it back to the lab. And they give you results within a few days.

Andy:

Well, last year they kind of changed their methodology and how they’re going to market. And we became one of their retailers for this program. And now this is a system that we’ve been recommending for years. And I trust it very much. It’s called a Home Air Check. So you can now go to the Green Design Center website and look up this air quality IQ testing kit. And it comes in three different versions. One is for mold. One is for VOCs and one is for formaldehyde and you can actually get a kit that has it all. And again, it’s very simple. It’s sent to you, you collect the air, send it back to the company.

And within a few days, we will get the test results and pass them along to you. And we get the test results because what we want to do is be able to interpret them and say, based upon what we see, here are some recommendations that could clean up your environment. Now, folks, do not take this as the end all be all in air quality testing. If you really need to drill down to the nitty gritty, you need to hire an indoor air quality scientist. Somebody who can come in with these large collection tubes. And you’re talking about several thousands of dollars.

Andy:

If you are looking to get a baseline, if you buy a home and you say, well, before we move in, let’s test to see where we’re at? And after we do our upgrades, we can test it again to see how much we’ve improved it. This is perfect. If-

Jay:

What are we looking at cost wise? Just to give a reference to the thousands of dollars-

Andy:

A couple hundred dollars.

Jay:

Oh, wait, there’s some savings.

Andy:

It is. And so here’s where I see this working, again, finding a baseline. Also, in situations where clients call up and say, what VOC meter do I recommend? I don’t recommend homeowners buy VOC meters to use themselves. And the reason for that is that there are so many things in the home that can cause inaccurate results from a handheld VOC meter. Somebody cooked breakfast two hours ago, and there’s still lingering oils in the air.

Someone walked into the house and was eating an apple or an orange, and it can spike the VOC content. Air movements, whatever you had on your hand, a lotion you had on your hand could actually cause the meter to spike. So this, the VOC indoor air quality test takes about 20 minutes. And it basically actually absorbs what’s in the air as opposed to giving the spot reading. And so it’s more of an average versus that instant spot check test. So I think this is a much more accurate reading. Again, not as accurate as if you were to hire an indoor air quality scientist who came into your home and did the testing themselves, but it’s very, very close. Matter of fact, this system was invented back with, if we all remember hurricane Katrina.

Andy:

And so hurricane Katrina blows through New Orleans and parts of Alabama and Texas, and we’ve got thousands and thousands of people displaced from their homes. And water recedes, and people are trying to move back in their home. Well, how do you know whether your home is healthy to move back into? They needed a way to test hundreds and thousands of homes at the same time to ensure that there was no elevated mold counts and other are issues in the home. So this company actually developed this test to be done in homes, without having people there to do it. And that out of something horrible, like hurricane Katrina came this technology of being able to test homes remotely, essentially. So it’s been around for obviously since then. So quite some time. It’s been really fine tuned to work very well, and it’s extremely accurate. So again, if you’re looking for this type of information and relatively quickly and inexpensively, this is the way to go.

Jay:

It’s a good one. We have to mention… You alluded to it earlier, the formaldehyde reduction testing. And that’s where you need a very accurate spot reading. So we’re always wondering in a remodel or build job, if there’s a off-gassing pollution problem, where is it exactly coming from? Because an ambient air examination is not going to tell us, yeah. It’s coming from the paint on the wall. No, it’s your floor. No, it’s coming from the carpeting. So the unit that Andy uses to do this, the sensor is one where you can actually test the actual surface and see what’s coming off of that specifically for formaldehyde. Specifically formaldehyde. And on our website, afmsafecoat.com, if you go to the frequently asked questions page and pull down onto the links page, at the top, you’ll see a report that we published a few years ago, where we actually did a test and you can see the unit and you can see how we tested it and you can see the results. And it’s impressive.

Andy:

It is. And yeah, you’re exactly right, Jay. I mean, those two tests together quite often, if somebody is complaining about an indoor air quality issues in the home and I consult on projects all over the world. And so I can only travel so far. I’ve got a small radius here in Wisconsin that I can travel to personally, but how do I help people in other parts of the country? So again, this indoor air quality test is the first way to go. Now what? Now we’ve got this information. And so locally, what I do is when somebody gets the results of the indoor air quality test, they go, oh, elevated formaldehyde, now what? Well, this is when I come in with the FRAT test. FRAT system. And I can put sensors on every surface in the house and actually pinpoint the exact surface that is the cause of the elevated formaldehyde.

Jay:

Yeah. Boy, and that really helps.

Andy:

Obviously, outside of my small radius in Wisconsin, it’s hard to do. However we get indoor air quality specialists around the country, and around the world, heck I just had somebody from Australia reach out last week to see if they could also get the FRAT system down there. So they can start testing in their area. And so we hope at some point it becomes bigger around the country that a more professionals are using the equipment, until then we have to rely on some of this other data and kind of do it the old fashioned way of going through that process of elimination to figure out exactly where the problem is.

Jay:

Yeah. Well, Jillian, if you’re listening to our show, I hope that was helpful. I’ve got one other one here, and this is a really interesting one. So this was from Gerald in Austin, Texas. “Hi, guys. I’m trying to figure out the best product to use on charred cedar Shou-Sugi-Ban to be in stalled on a kitchen wall. Basically, I don’t want the charred cedar gator effect to fall off. And I’d like the product to be wipeable with a damp rag when cleaning. So basically I need something that bonds well with oily wood and has a poly light coating to protect delicate char from flaking off, you guys have a recommendation? Thanks so much. Gerald.” Well, you know what this is, right? You’ve seen it, right, Andy? You know what it is? Oh yeah. It’s an old Japanese technique where you actually char… You burn the wood. And don’t they stack it like in a shape and burn it from the inside and then turn it? I mean, have you seen it done, Andy?

Andy:

I believe so. It’s almost like the idea of scorching wine and whiskey barrels.

Jay:

Yeah. Right, right.

Andy:

I am not exactly sure of the technique of how they do it. I have seen it. I’ve got customers use it. I even worked with a company called ThermaRay that has this for exterior cladding. Absolutely beautiful. For those of you who don’t know it, it’s Shou-Sugi-Ban. It’s S-H-O-U and then S-U-G-I-B-A-N.

Jay:

Right.

Andy:

Shou-Sugi-Ban. If done correctly, it doesn’t need to be sealed. And so this is where you’ve got to be careful because if you go too far with it and you really alligator the wood, it can become brittle. So I think one of the real artistic points of this product is the fact that they have figured out the exact charring method to get to that point without causing too much loosening of the actual wood.

Jay:

Yeah. And he’s got some other issues, he wants to be able to wipe it with a rag. And I’ve seen… There’s a restaurant just down the street from our office here and they did it on the outside. It’s beautiful. But I went up and I put my hands all over and touched it because I just loved it. I’m not thinking I’m going to wipe it down with a damp rag. I mean, it’s got texture on there and I just don’t think it would make any sense to do that. I’d be using a brush or something if I was going to clean it at all. And then he is also worried about the oiliness of the Cedar. So he is talking about wanting to put a poly. A what? An oil or water-based… Well, water-based poly over an oily wood?

Andy:

Well, it’s interesting. I mean, you can do this technique to just about any type of wood. I suppose it works better on certain species over others. You know pine works really well, but it depends on how far you take it. Now, one of the questions you and I have gotten over the years, Jay, is how do you seal up the smell of burnt wood, right?

Jay:

Yeah.

Andy:

If somebody has a fire in their home, the wood is smoke damaged. How do you seal that smell? And so this is where this is kind of interesting because you’re purposely burning the wood. You want to be able to seal it so you can clean it. The problem is if you put a water based sealer over charred wood, it’s going to smell like charred wood times a hundred.

Jay:

Yeah.

Andy:

The whole house is going to smell like you had a fire in the house.

Jay:

Yeah, exactly.

Andy:

So the only way to properly seal it would be to use a waterless sealer. So you may have to play around with something like a clear shellac.

Jay:

Yes. Shellac would be my idea. What about oiling? What about oiling the wood? I mean, so it’s black. I mean, if you oil it, it’s going to get blacker.

Andy:

Well, the problem comes down to how textured the wood becomes, because if it’s really textured, really alligator, or scaly, let’s say…

Jay:

Scaly is good.

Andy:

Oil will get into those deep crevices of the scales and never dry.

Jay:

You got it. That’s not going to work.

Andy:

So I think if you did that, you would have to go pretty heavy with an oil solvent blend. A lot of solvent so it flashes off and then of course you increase the toxicity. I think my recommendation after now noodling on this here would be a pure, clear shellac.

Jay:

Yeah. I’m thinking the same thing.

Andy:

And shellac folks is a… It’s a natural material. It’s the sort of the shell of the Lac beetle that is melted into pure alcohol. And once the alcohol evaporates, completely flashes off, it leaves a completely nontoxic surface.

Jay:

Yeah. And it does. And it will control the smell of smoke.

Andy:

Definitely.

Jay:

So you’re right. You’re right. That’s a very good point about water activating the smell. This happens a lot folks, you get what’s called flushing. So water gets on a surface and all of a sudden, the surface starts to really smell. And that’s because water’s activating those dormant chemicals. And as soon as they re-wet it, they start to smell again.

Andy, we’ve walked into it where people have done a remodeled job… A refinishing job, and they put a coating on it. One of the AFM coatings, or another coating, and all of a sudden the pollution problem got a lot worse. And they’re wanting it to go the other direction. Why isn’t it getting better? It’s getting worse. What’s going on? So we talk about flush. Generally speaking, folks, flushing will end. There’s an end point in flushing. They say that water evaporates. And then everything starts to calm down, the sealer drys. It starts to control the surface. And then you’re fine. But it is a little bit disturbing to some folks because they’re anticipation is a little bit different than what’s happening.

Andy:

Exactly. And when you’re dealing with natural aromas, like the smell of wood, the smell of burnt wood, smoke, even the smell of cedar, that tannic acid of cedar.

Jay:

Pine. Pine.

Andy:

The flushing actually makes it worse and it never goes away. So you really have to be careful of that.

Jay:

Well, I thought that was an interesting one. Shou-Sugi-Ban.

Andy:

It’s beautiful, it’s absolutely beautiful.

Jay:

It is beautiful.

Andy:

And you can, you can actually buy it with different levels of burn, I guess you can call it, going to different stages of it. And anywhere from just a real light torching of the surface, all the way to that full alligator scale look. It’s really, really beautiful.

Jay:

I think we’ve had some good mailbag today.

Andy:

Well, I think that’s great to start the year off. That’s for sure.

Jay:

I do too. I do too. Fantastic. Fantastic. So, Andy, what do you want everyone to know?

Andy:

Well, I want everybody to know that we are back at it, finally. I mean, it’s been a long, long holiday off and I have nobody to blame, but myself-

Jay:

Well, you know that our listeners are probably thinking those slackers, what are they doing?

Andy:

Exactly. Exactly. But now really looking forward to this year, we’ve got a lot of interesting topics that we’re already lining up. A lot of good interviews lining up. And as always folks, we really appreciate not only these email questions, they’re are just wonderful. But also recommendations of topics because we’ve been at this now. This is the beginning of our fifth season, Jay.

Jay:

Boy, I can’t even believe it goes by so fast.

Andy:

That’s so many, so many episodes, and at some point you start to think of what other topics are there? But every day, every week we get emails from customers saying, why don’t you talk about this? And so we really appreciate that. Any ideas you have, feel free to reach out andy@degreeofgreen.com. And now that we’re back at it, we hope to be doing this. I want to get back on the once a week…

Jay:

Schedule.

Andy:

… Schedule again, Jay. That’d be nice.

Jay:

Okay.

Andy:

But we’ll… It’s tough folks. We love doing it, but it’s just a matter of finding the right time where Jay and I can both get together and-

Jay:

Well, yeah. And I think one of the things too, is we want to try to get some more interviews in this year because we always have a lot of good talks with people that we think are important in our industry. And so hopefully we’ll be able to get as many interviews as we did last year and maybe some more because we love interviewing people.

Andy:

Jay, as always, it’s been a pleasure talking with you and, folks, will be back with you soon.

Jay:

Adios everyone.

View Transcript PDF

In this episode…