Podcast

NTE Podcast: January Q&A

NTE Podcast: January Q&A

Well, its finally cold here in Wisconsin, so there’s no better time to stay inside and work on small home projects. Today, Jay and I answer a number of listener questions to help with those projects. I also get to announce a bit of exciting news!

iTunes

Spotify

Transcript

January Q&A

Andrew Pace: Welcome to the Non Toxic Environments podcast. My name is Andrew Pace. Every week, my cohost Jay Watts and I will discuss healthier home improvement, ideas and options. Thank you for finding us and please enjoy the show.

Hello folks. Welcome back to Non Toxic Environments. Jay, we have another Q and A session we’re going to do today because let’s face it- we’re all sitting at home, looking at things that need to be done around the house. And, we all got a lot of questions, so hopefully you and I have got some answers.

Jay Watts: Yeah, I hope so too. You know, that’s so true. I think people are got some time on their hands. They’re going, hmm what about this project? What about that project? We’re getting a lot of these questions all the time and we expect it, we want it, we ask people to do it. So here we go, I’ll we’ll start out.

This is an interesting one because I’ve never really thought about this. So this is from I don’t know if it’s a man or a woman, but it’s Terry in Boston, Massachusetts, and Terry asks “what’s the best product to seal plastic casings of electronics to prevent off gassing of flame retardants inherent in these products?”

Andy: Ooh boy.

Jay: Now first it’s a question I had not really had anyone asked me about electronic wiring, but what throws me here more than that is a flame retardant on the electronic plastic casings? So he’s talking about like a computer case, not the cords, but the actual box, is that plastic casings?

Andy: Yeah, that’s what I’m thinking. I’m thinking the gray plastic, I’m thinking the black plastic case of a stereo. Or a television in the back. Quite often I get calls from customers and I’d refer them to our website and they’d say, I can’t use the internet, I’m sorry. I can’t use a computer because of what’s coming off of the computer, not only the electromagnetic fields, but the problem with the actual smell of the electrical components getting hot. So I do know that that’s an issue. I also know that yes, flame retardants are added to plastics specifically when it comes to electronics because you kind of have to.

Jay: Yeah. This is reminding me of the other questions we get asked about. Not necessarily plastic per se. Actually, it’s another question I’m going to bring up later on, so it kind of dovetails with it. But we get asked to go over, for example, people want to seal cabinets and it’s got melamine on it. And melamine folks is just a very thin laminate. That’s glued to a cheaper substrate, like medium density fiber board or plywood. You see it a lot in the lower end cabinets. The outsides are done and the inside of the shelves are done this way. People want to seal that material. And it’s pretty difficult to the difficulty is getting something to bond to those surfaces.

Andy: Well, that is the first difficulty and is getting something to bond to the plastic. And I’m not saying it’s impossible, but it’s not probable. First of all, you have to make sure that the plastic is completely cleaned and Jay, AFM has some experience in this. AFM maybe you can just talk a little bit about, working with one of the major auto manufacturers, you guys supplied one of your coatings tinted black to help seal black some plastics.

Jay: Yeah. Right. We have actually have two great stories that involve car manufacturers. So the one Andy’s referring to is that work we do with Hyundai. And Hyundai actually had a component, a plastic component in their vehicle and similar to the other car story, which was the BMW story, which Andy’s told before. They needed to seal this plastic. I can’t remember exactly where it was. It might’ve been in the trunk compartment. Again, it might have just been in the back part of the car, but they wanted a sealer over that. We tinted Acrylacq. Acrylacq is our Safecoat, a water-based replacement for solvent-based lacquers. Lacquers are typically used for furniture and cabinets of woodwork. They needed an alternative. And so we were able to provide them a tinted version of our Acrylacq in black. And then they took that into the factory and they actually sprayed these components with the tinted Acrylacq and it solved their problem. Are you going down the road here because we might be able to make this recommendation here in this instance.

Andy: I guess what I’m saying is, and I said before it’s possible, but not necessarily probable that we can get something to work. The reason is in a factory setting, you’ve got components that are uber clean and let’s face it before it was sprayed with Acrylacq, I would, they did some type of a solvent wipe.

Jay: I think they probably did. Yes.

Andy: Plastics have a tendency to be very oily when they first come out of manufacturing and they release oil for a long period of time, which is why you get like that smear of oil on inside of your windshield in a car. Yeah. So that you gotta clean the plastic to a point where it can accept a coating, especially a solvent free water-based coating like what AFM offers.

Jay: Yeah. So are you thinking this is acetone they might use?

Andy: Probably yeah. Or isopropyl alcohol. I’m also thinking that they’d probably be using the Hard Seal and not the Acrylacq. And here’s why- Acrylacq can be put on very, very thin with specialty spray equipment and homeowners don’t necessarily A) have this and B) you really don’t want to spray into a computer case or a cereal box because of all the holes. So this is somebody you gotta be really careful with. Let’s say, cross our fingers, that you were able to get Hard Seal after you wipe the surface with isopropyl alcohol, it’s clean. Let’s say you put on three really super thin coats of Hard Seal, and it actually adhered? Will it seal up the off gassing from that surface? Probably. However, here’s the caveat. It’s not going to seal up the outgassing from the inside of the case.

Jay: Yea, so we deal with that all the time. When people have a sandwich problem, you’ve got something in a sandwich down at the bottom, it’s in the middle, somewhere along the line here. And they want to make sure that if we seal the top, we’re going to seal everything below. And I’ve constantly said, well, it doesn’t work that way.

Andy: It doesn’t work that way. Here’s what I tell most customers: even the absolute best sealers on the market, the Safecoat sealers, will seal up what’s off gassing directly from the surface it’s attached to. The further, you get away from that seal, the less likely it’s going to do any work. So people will ask all the time, and I know this is a tangent, but they’ll say, we’ve got urea formaldehyde based installation in our walls. Can we paint our walls with Safecoat and seal it up?

Jay: Yeah, I get that one.

Andy: No you can’t because you’re not actually sealing the offending surface. You’re sealing something way beyond that.

Jay: It’s interesting because then they’re like, Oh, now what do I do? Well how do I solve that problem? And you know, the answer can be if we’re going to seal it, we got to get to it. And if you got to get to it, that means you’ve got to start taking apart. And are you ready for that? Are you ready for deconstruction? Usually they’ve just finished construction. If you say you’ve got a deconstruct, it’s like, are you kidding me? And I’m saying, I’m sorry. I wish I could tell a joke, but I can’t. No, you’ve got to do that if you want to deal with it. So I’m going to stick with this a little bit, Andy, because I think people that are listening is probably going okay, well, what do you guys think we should do? We don’t want to deconstruct. Then we have to start talking about you’re going to have to manage your air quality and work towards the goal of, and I hate to say the words because people get freaked out, waiting it out. We got to wait it out and they go, well, how long is waiting it out?

Andy: Well, depends on what’s releasing, from formaldehyde. If we wait it out maybe your grandchildren might be able to live there.

Jay: I was just going to say, it’ll be way beyond us.

Andy: Open up the walls and get rid of it.

Jay: Yeah, exactly. Or think about, and we’ve talked about this in other shows and that is how do we manage our air? How do we purify? How do we do all that stuff? There’s other mechanical methods to try to fight this, but it’s always questionable. Sometimes it’s better just to bite the bullet and just get that stuff out of there and start a fresh, start with the good stuff. And then you’re taken care of. I know folks it’s expensive. You’ve just moved in. You don’t want to have to move out again. It’s a real headache, but sometimes it’s better to do the massive surgery and not try to bandaid an idea.

Andy: Jay, this actually brings up a call that I got today and I’m going to talk about the call. I don’t have it written down because it just came to my mind.

Jay: Okay. It was fresh in your mind. Go ahead.

Andy: A very good client called up and said, we ripped up the carpet in our house as your suggestion always says, and we found painted wood floors underneath, not stained and sealed, but painted wood floors. They said well, because our home was built in the forties, we went ahead and had that paint tested and it is lead based paint. So she said, what are our options? And you know, keep in mind, we’re trying to be budget friendly. Okay. I will say this in the close to 30 years of selling building materials, maybe three times have I had a customer say, you know, budget’s not a concern. It’s always a concern. It’s a concern for me, it’s concerned for all of us.

Jay: Even when people have all the money in the world to spend is still an issue.

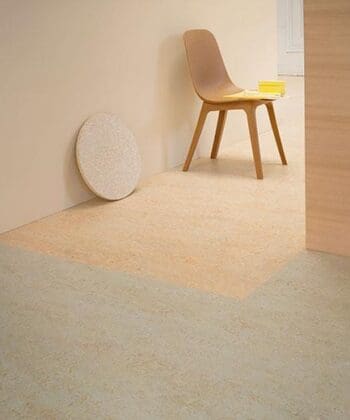

Andy: Is it. Nobody wants to overpay. Nobody wants to buy someone they don’t really need. So in this situation, this is what brought this up. There’s two ways to go. Number one is you can apply a floating floor over the surface, floating wood, floating cork, floating natural linoleum or a floating luxury vinyl plank, something like the Cali Vinyl PRO.

Jay: Yeah. So tell people go quickly with the floating floors. Because some people may not know that word. The terminology.

Andy: So a floating floor essentially is kind of what it sounds like- instead of being fastened down to the floor with nails or glued down to the floor, it actually, these flooring materials now click and lock together. So they’re plank floors, installed by locking into each other, kind of like a puzzle. With long straight pieces and it does not get fastened to the floor, the whole floor kind of floats over the surface. You don’t feel it. You don’t notice it, but it is floating. In this situation specifically, why it’s so important is because it does not disturb what’s underneath. You’re not actually fastening to the floor causing, lead dust to come out. You essentially put down a vapor barrier over the surface and then apply your floating floor.

Jay: So there’s no need for an adhesive here. You don’t have to do any of that. It’s just like you put down your barrier, you lay down your floor and it’s done.

Andy: And there’s no need for a lead remediation contractor to come in. Not at all very expensive. That’s option number one- which I like to call kicking the can down the road. Now all of us would in this situation, think about do I really want to deal with it? Or do I want to just cover it up, kick the can down the road and then maybe somebody else will have to deal with it, but it’s not going to be me. This is a tough decision to make because you know, face it folks, somebody eventually will have to deal with it. It’s going to be somebody’s expense. You wish it could be the expense of the people who did it originally or more so the manufacturer of the lead based paint, but they don’t pay for things like this. So somebody eventually will have to deal with it. So what’s the answer.

Jay: Yeah. The question is what’s your legacy? You know, what do you want to leave behind? My sense is that because, of course budgets are at the top of the heap here, they’re probably going to say, I’m going to pass it on. Yeah, I’m gonna pass it on.

Andy: I’d say eight out of 10 times. That’s what happens. Yep.

Jay: Yep. Yep. So what’s the other ideas you have? So we’ve got number one was putting a floating floor. What was number two?

Andy: And the other idea would be you can try to put other coats of paint over it that’ll act as a somewhat of a lead encapsulant.

Jay: That’s the cheapest way.

Andy: But that’s also, you may run into problems here because in order to get a good bond on an old oil-based surface, which most of those lead based paints were oil and solvents. You have to do a little sanding though. Now you’re opening yourself up to that issue. And now we’re talking protective equipments and really being careful. Hence just covering it up. A third option is to strip the wood, which is also you’re bringing in professionals. You’re bringing in equipment. The downside with this is you’re never really getting in between the pieces of wood. Fourth option is to tear the wood out, down to the sub floor and start from scratch.

Jay: Yeah, I guess that’s another question too. What kind of wood is underneath that paint? I mean,

Andy: Chances are it’s an oak or maple. What they used to use.

Jay: Maybe it could be very nice. And if there was enough wood left there, that would be an option to get all their old crap off there, get back down to the wood. Then you can clear finish it. You can stay in and clear finish it. This was in our house. We had carpeting when we bought our little house, we had carpeting everywhere and we pulled it out and lo and behold, beautiful Doug fir. So all we did is we sanded it and finished it with Polyureseal, our Safecoat product, the Polyureseal BP. Beautiful, beautiful, beautiful. I mean the one was 75 years old.

Andy: Hopefully that’s how you find it. Hopefully you’re lucky enough to find finishes that aren’t led based or wood that’s basically bare and you can deal with it. This situation there isn’t that, the issue is the lead. And so you worry about paint that seeps down in between the crevices of the wood and get that out with sanding. So it really you’ve got four options. You’ve got floating floor over it (kicking the can down the road), painting it and maybe would disturb and cause lead dust because of the preparation of the surface, stripping it and removing it. What is the right answer? I don’t have a right answer for you. The right answer is I think something every individual has to think about and say, how long am I going to be here? How long is my family going to be here? Am I raising children on this floor? Because we all know lead is obviously a toxin. It’s a heavy metal. It’s a problem ingredient, it’s typically classified as a developmental disorder ingredient. And so typically children over the age of 15, 16 aren’t affected anymore by lead.

Jay: And it’s more a long-term reaction too. It’s not like an evaporative, like a chemical is floating around here and you could have a reaction pretty quickly. Lead takes longer gets in your system and it takes longer for that bad things to show up. I’m sure you said this to the client- if you want to see what’s underneath the paint, go out under the edge and get rid of some of that paint out there and let’s take a look at this wood and see if this wood is decent.

Andy: Right. Well, that’s a huge issue too, because if the wood is still in good shape, but it’s just been painted over, it’s hard to say. So that’s basically what I said to the customer. You have to decide what is your plan for the home. Can you feel good about essentially kicking this down the road, letting somebody else deal with it? But folks whenever you buy an existing home, that’s part of the deal. The deal is you’re buying a home as is, you’re buying it and everything that is in that home is now yours and it’s your investment, it’s your asset, but it’s also your problem. As we have said in episodes before, this is why if you had the choice between buying existing and building something new, I usually choose building new because I can choose every material that goes into that home and there are no surprises. Really depends on how adventurous of person you are, what you want to take on and all those other things we talked about.

Jay: Yep. Okay, moving on. This is from Boca Raton, Florida. It’s a follower named Naomi. Naomi’s asking, “I’m looking for advice on how to properly seal and paint MDF cabinets.” Okay well, we’re thinking slam dunk on this one. But then she puts this sentence in, “it is recommended to not use water-based coatings because they will cause the MDF to absorb liquid and fall apart, non water based acrylic and latex based paints are…” This is funny. And then she writes the next sentence, which is… Well, you can’t say non water based acrylic water-based is acrylic but [she goes on] “Non water-based paints are recommended for these types of materials.” So she’s saying if you don’t use oil-based products here, your MDF is going to fall apart if you use water. Yup.

Andy: Well, I’ll say this, MDF cabinetry is there’s pros and cons to this. Pros, the cost of it, easily lower cost, more affordable. MDF wood itself is usually more dimensionally exact than plywood is. Three quarter inch plywood is kind of a nominal three-quarter inch. Three quarter inch MDF is dead on three quarters.

Jay: It is dead on.

Andy: Again, there’s benefits. MDF is heavier, so it’s a little more difficult for independent cabinet makers to work with. Finishing is an issue. A lot of times you’ll get MDF has pre-primed and the pre primed material will accept a water-based finish. But I specifically have had issues with using even the AFM Ecolacq on MDF.

Jay: So tell me about this because in my experiences, share with me what you know then I’ll share with what I know.

Andy: So in order to apply a water-based finishes to MDF. It’s very tricky because as soon as you start to hit it with a water-based product, it starts to swell. So you have to start out using something like AFM is Transitional Primer, but it’s got to go on extremely thin. This is something where I do not recommend a homeowner to do themselves. This is something where you need to bring a professional finisher in. Transitional Primer by itself is typically pretty viscous. So you need to add some water in order to thin it out to spray it properly, which adds to the problem. So again, putting it on the first coat, almost a spit coat, I’d rather have you see spots that look undone and you have to start to build coats. And Transitional Primer is a very good primer for problem solving, but it’s not a very easy primer to sand. Which is another reason why we want you to put it on really thin for the first coat, because we hope after the first coat it’s raised some of the grain, you can sand it and it’s not too hard to sand. Now, after that, I would put on another very thin coat and then probably a third coat, more at full strength. And then you start putting your finish coats on. And I will say that on MDF, I have seen seven, eight coats of Ecolacq go on, because it’s really difficult to get MDF, perfectly smooth using water-based coatings. MDF, although feels smooth, if you look at it under a microscope, it’s very pitted. Once you start putting coatings on you actually magnify the problem and it comes out looking like it’s really bad orange peel effect.

Jay: Yeah. I’ve seen that.

Andy: That’s the experience I’ve had with MDF. This is one of those questions I like to answer before somebody pays to have their cabinets made in MDF. Let’s think about the project a little further ahead and say, how might you finish these before we deciding on a substrate?

Jay: Most of the time, and I think they think about the particle board MDF. Now they think about it and they go, well, this has in the construction of MDF, but the surfaces that they’re treating are not the raw MDF. The MDF is the edges. It may be the bottom of a shelf. When was the last time you saw just MDF cabinets? No laminate, no veneer. I can’t remember when. Maybe I was in college in 1972.

Andy: The last time I saw it, it was actually pre-primed. And so that’s what I’m saying. I believe that most often you’re going to find these MDF materials that are pre-primed.

Jay: They’re going to be painted.

Andy: Well typically, if you have cabinetry made of MDF, it’s going to be covered with something like a melamine or a wood veneer.

Jay: Right. Right. Right.

Andy: So, at that point then everything I said is just inaccurate.

Jay: I know, you see what I’m saying? You agree? I’m a lot of people who say I got MDF, but all they’re talking about is just those little exposed areas. Or maybe they thinking, you know what, it’s MDF and it’s got a veneer on it. So I need to seal all of it because all the MDF underneath everything else, it’s going to be off gassing. And again, it’s the same thing.

Andy: I will say this when you get some of the less expensive cabinetry that even has a wood veneer on the exterior of the MDF, the inside sometimes is raw. And so we’re talking about, let’s just seal it up and not really worry about what it looks like is nobody sees it anyway.

Jay: We’ll put this one aside, but the only thing is I have not seen that kind of swelling that you were mentioning with water, and I guess if you had real tight tolerances, where things had to but up, or touch each other without, then I could probably see that. I’m going to do some experiments. I’m kind of fascinated with this. I want to see what’s going on with it. Here’s one we’ve talked about this before and the answer is pretty simple, unless you’ve got a new answer. The answer is a short two letter word- No. “Is there a safe plumbing glue?” Plumbing glue? I think they’re talking about the stuff that you glue your PVC pipes together with.

Andy: So the answer is no, but let’s talk about that for a second. When working with PVC or CPVC, which is typical for drain lines, you have to use an adhesive for the joints that literally melts the plastic. And you stick the two together and after a minute they’re stuck together, that’s it. It’s just plastic to plastic. So in order for that to work, it has to be what’s called a cyanoacrylate adhesive. It’s literally solvent that just melts the plastic. So you can get it stuck together. And there is a PVC glue on the market called Gorilla Glue. Don’t get that confused with the regular Gorilla Glue. I’ve had customers talk about this for years. But from what I understand, it is a lower VOC, lower solvent version of PVC pipe adhesive. However, no plumber that I’ve ever worked with will use it. They don’t trust it. They don’t trust it because they’re used to the solvent’s doing the work and painters, we have the same issue. They want that smell because if it smells, they know it’s going to work. So I guess that’s at this point, it’s kind of caveat emptor. We don’t know how well it works. People talk about it, but professionals don’t use it. At least the professionals I’ve worked with across the country. I’ve reached out to the company several times for more information and they are not willing to share information about the product. So at this point, I would say, um, it’s up in the air now, my recommendation is to use plumbing materials that don’t require that all your water lines use PX+EX and use press fit fittings. There are some plumbers now that are starting to use polypropylene pipes, which is really interesting because polypropylene is a far safer plastic. So there are options out there

Jay: Wasn’t there a hack we had on our hack show about wrapping pipes that have been using the solvent glue with tape?

Andy: Yeah, exactly. And that’s a great thing to bring up, Jay. There was a hack on this and which is in a situation where you have to use the regular PVC pipe adhesive, your best bet is to after that joint is cured and the contractor’s gone wrap the pipe with a layer of Dennyfoil, or even better is taking HVAC metal tape. HVAC metal tape that used for duct work and actually wrap around the joint and let it go a few inches up a few inches below the joint, and that will seal up the off gassing from that solvent based adhesive.

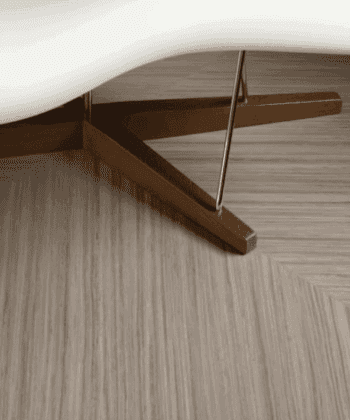

Jay: You’re touching on this fact that there’s resistance in the plumbing world. The guys don’t want to use it because they don’t trust it. This is it’s reminds me of how it used to be. Thankfully it used to be years ago with all of the products we talk about that we were breaking with tradition. The tradition was I’m going to use the conventional stuff I’ve been using for decades. And I’m really kind of resistant to anything that is not tried and true. As I said, thankfully, you know that those attitudes are changing. People now recognize because we’re mature enough now, people are recognizing that, Hey, there’s no sacrifice here in terms of functionality. In fact, it can be sometimes a lot better than what they’ve been used to using, but there’s that myopic “I’ve done it this way. This is the way it works. I’m not willing to.” And I can understand from a plumber standpoint, the last thing the plumber wants to do is have a flood on his hands. You use that glue and my pipes didn’t stay together and guess what? Uh, no. Do I have one more? Well, I do. This is kind of the tail end of that. First question was “how do I seal plastic casings?” We see this [one] more often, “what’s the best way to seal luxury vinyl tile to stop off gassing and seal in the VOCs?” And the second part of the question is “how often does a sealer need to be applied to contain the VOCs?” that’s from Kathy Newkirk.

Andy: You know, and this is a good question, I’ll answer it this way. Do you know that we have to seal out or seal up VOCs? This is an answer that I’ve been giving to customers quite often lately and I find myself becoming much more comfortable saying this. Let’s figure out whether things have to be done or not. Let’s just not do that because we think we have to. Here’s why- once you get into the habit or into the schedule of sealing your luxury vinyl tile floors, and you can seal them with three very thin coats of AFM Hard Seal, provided that it adheres and you do tests so on and so forth. But once you start that, this is something you’re going to have to do every couple of years. Because it’s not as hard as the tile itself and it’s going to scratch a lot easier, but the flip side is at least your tile is sealed. So now do you have to? Do you know that it releases volatile organic compounds? Do you know it releases formaldehyde? Do you know this is something you have to really dig into? And yes, number one thing I say is I would love to sell you products, I’m a sales company, I sell products, but I do not want to sell you product when you don’t need it and if it’s going to make your life more difficult. So let’s find out, maybe through some investigation, maybe it’s through a consult with myself or with Jay. Maybe we find out what is the manufacturer that you used? Have you done the research on what it releases? Do you need us to do the research on that? Is that something we can test? And then let’s figure out the next best step. And this folks, this ranges to all of the materials that people ask about, the materials that we sell, I’m very, very comfortable in knowing when I can use one of our products and when maybe it’s not a good idea and I’m happy to tell you that. I don’t want to sell you a product you don’t need, I never want somebody to call me back and say, I found out that my floor was free of this anyway, I guess I didn’t need your product. There’s a sour taste in your mouth and we don’t want that.

Jay: Right. Not at all. You know, I know you’ve done it too but sometimes I say, you don’t want me, you don’t need me. They’re like what? And I go, yeah, it’s true. That’s what I think. I would think that when you start to talk about the higher end products, the company that makes them is probably going to be talking a little bit about how great it is. Now that that language is including this idea of what’s in it that’s not going to hurt you. So if you can do that background research, as Andy’s alluded to and find out, ask them the question- “do we need to be worried about off gassing? And if you have any documentation that would show that this product is very low or no in the off gassing realm, then that’s just another reason why I want to do business with you.” So, it takes some research. I think there’s a lot of stuff that floats on the internet, you get different differing opinions, people get confused. Then they’re frustrated.

Andy: Well when I ask them why do you want to seal it up? And they’ll just say, well, let’s assume it’s releasing something.

Jay: Right, right, right. They jumped to a conclusion because all the stuff they’ve read about how bad vinyl is.

Andy: Right. All right. Here’s a link. Make a 15 minute appointment with me. Let me actually ask some questions that really digs into how has it installed, what’s underneath, what else was done at the same time, maybe what you’re experiencing, if you are experiencing any issues, maybe it has nothing to do with the actual form material itself.

Jay: I was on the phone the other day with a gal and she was talking about something she wanted to do and she brought up a product and I said, well, hang on, I’m on the internet right now let’s look it up. I looked it up and I go- that looks okay to me, I think you’re going to be okay with that. I explained it to her and she was like, that’s fantastic. She got a nice little consulting job for basically gratis, which I’m glad to do. It’s easy like that. But you know, there are very complex issues and it’s worth the time and the money if you’re going to hire Andrew or myself to do these kinds of investigations for you, A) we love doing it and B) it’s going to save you a lot of headache and hopefully we can guide you down a path that’s going to put you in the wellness world and that’s what this show is about.

Andy: You got it. And on that note, let me just say this, boy, there’s a lot of projects going on right now. This week we’ve got three new homes, three new couples that are building new homes that we contracted with this week. So this is a hot topic across the country. Very hot topic.

Jay: You’ve got something with this fellow that I just connected you to in Toronto.

Andy: Oh yeah. He’s got two homes going up in the Toronto area. I just spoke with an interior designer and health coach in Idaho yesterday and she’s got things going on.

Jay: Exciting times.

Andy: It is. It really is. On that note, I can officially announce that… I may have talked about this before, but something that we’ve been wanting to do for decades now is build a model healthy home and we have finally secured the land. So it’s official, we’ve got the plot of land for the GDC/Building for Health Non Toxic Environments healthy home. We are in the design process right now and once we start to really dig into this, we’re going to start recording some video about how we’re designing the home, the things that are most important to us in our project and from that, it’s going to become a how-to, so we’re excited about this. It’s a great time in our industry right now.

Jay: Giving me goosebumps, Andy.

Andy: Jay will be out here, hopefully this summer to help us with some of these recordings.

Jay: Put me in a big mack and give me a shovel. I’m good.

Andy: Now it all depends on obviously what’s happening with the pandemic and then we’ll all be safe and secure. I’ve already had the COVID. I’m set for at least a good six months.

Jay: Yeah, I’m at an age now where I have… they’re tiering it out here in California. So, healthcare workers are getting it first, but here’s a weird thing. I’m old enough to be able to be qualify for the vaccine, but I haven’t gotten it yet because I’m not in that tier here in California. Everyone around me, that’s a lot younger than me. They’re getting a vaccine and I’m going, wait a minute. What is up with that? Well, I’m not worried. I’m going to get it.

Andy: Should out to Gavin Newsome out there in California. Jay Watts is essential and he needs to get his vaccine.

Jay: Gavin, are you listening?

Andy: All right folks, that’s this week’s episode of Non Toxic Environments. Jay, great questions. Thanks for bringing those out to us.

Jay: Oh yeah. Well, they keep floating in and we love them.

Andy: We do. And so please keep sending Jay and myself questions that we can answer here on the show. My email address is andy@degreeofgreen.com. If you have any feedback about the show, we greatly appreciate it. And of course we have to say, if you listen to us on the Apple iTunes platform, it would mean the world to us if you could take a few minutes and leave us a rating and a review on the show in the show header. It’s very important for new listeners in their quest to find a show like ours. Now in the last week Jay, we have reached in the top 10 in New Zealand.

Jay: Okay, we’ll keep moving up in New Zealand.

Andy: Hong Kong, we hit number two. The number two show in all of Hong Kong under home and garden.

Jay: I would love to hear the translation of our show.

Andy: I don’t know if they can translate all my ‘ums’ and ‘ahs.’

Jay: They probably speak English very well.

Andy: But I will say this, it’s not necessarily the numbers for me that get me excited, it gets me excited that so many people around the world are finding us.

Jay: That’s what I love too.

Andy: It’s so exciting. And so a shout out to all of our fans all over the world. Thank you so much. Here at home, we love you guys and we appreciate you listening. And Jay, we’ll talk to you again next week.

Jay: Sounds great. Andy, have a good weekend.

View Transcript PDF